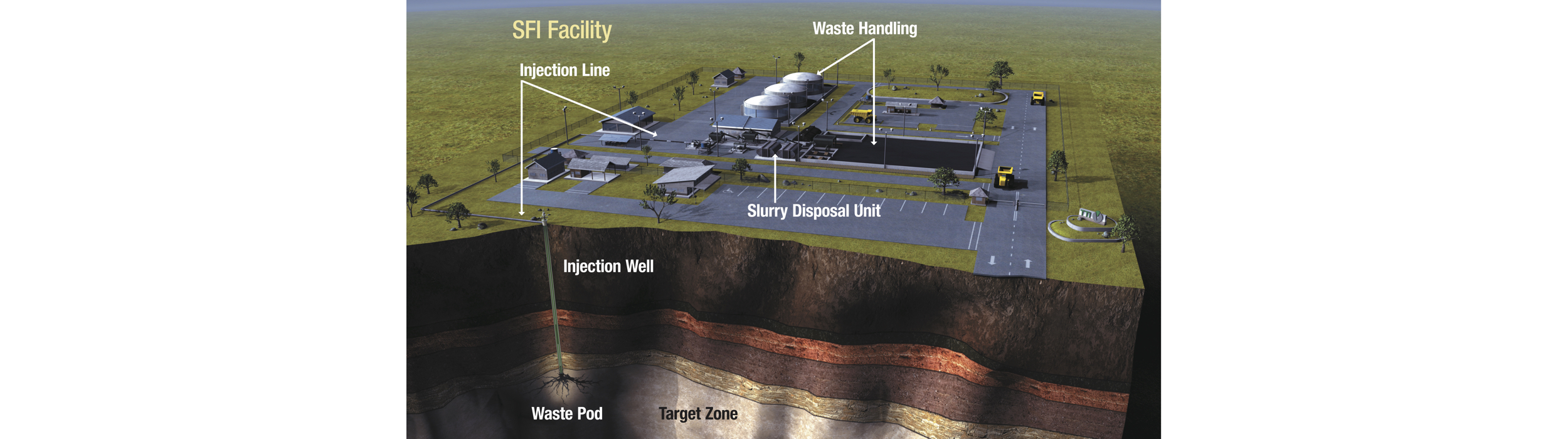

The Slurry Fracture Injection™ (SFI™) process is an advanced deep well disposal technology characterized by:

- Lower injection rates and pressures (compared to existing HF methods).

- Continuous, cyclic injection.

- Development of near wellbore, short, complex fracture networks; creating a more uniform ‘stimulated rock volume’ around the well.

- Gradual propagation of the ‘stimulated rock volume’ from the near wellbore area out into the formation.

- SFI incorporates robust Process Monitoring & Process Control systems.

- SFI process mitigates the development of induced seismicity or fault reactivation.

- The SFI process is ideally suited to unconsolidated, friable (un-cemented) sand formations; or in naturally fractured rock systems.

Implementation of the SFI process for ‘Zero Discharge’ deep well disposal results in significant environmental advantages, including:

- Protection of underground sources of drinking water;

- Elimination of run-off & contamination risks to surface and groundwater;

- Elimination of surface land use impairment;

- No induced seismicity;

- Elimination of long-distance transportation risks and costs;

- Greatly reduces long-term liability to operator/generator.

- Safeguards human health by reducing and removing pollution from the biosphere.

Special emphasis is placed on the implementation of industry Best Practices and Process Control to maintain waste containment in the target formation interval, reduce operating costs, optimization of injection operations, maximize formation storage capacity, and maximize injection–well life.

View/Download the Fact Sheet ( 中文 | Bahasa Indonesia | عربي )

Video Presentation

Terralog Technologies Inc. company profile highlighting services and benefits of TTI and SFI technology for deep well disposal of waste.

Duri – PT Chevron Pacific Indonesia

The Duri oilfield is one of the 141 oil fields operated in Sumatra, Indonesia by PT Chevron Pacific Indonesia under a production sharing contract with the Government of Indonesia. Discovered in 1941, the Duri field is one of the world’s giant oilfields and the biggest steamflood operation located in the Rokan block with peak oil production of 200,000 bpd (31,000 m3 per day). The in-situ formations of the Duri field are unconsolidated sands; coupled with a steam flood operation they are susceptible to producing large quantities of oily viscous fluids as a by-product from the oil production. Up to 400 m3/day (2,500 bpd) of oily viscous fluids are generated at five oil production Central Gathering Stations (CGS) in the Duri oilfield.

Using Slurry Fracture Injection™ (SFI™) , Terralog has successfully implemented one of the largest deep well disposal projects for E&P waste streams at the Duri oilfield in Indonesia.

Terralog has been operating this project since December, 2002.

The primary waste stream for the SFI site is Oily Viscous Fluids (OVF; i.e. oily sludge)

From December 2002 to June 2017, the Duri SFI project has disposed of the following waste streams:

- Approximately 5.9 million m3 (37 million bbls) of waste water and produced water (used as mix-water for the SFI process).

- Approximately 1.6 million m3 (10.1 million bbls) of OVF.

The SFI project has now made the Duri oilfield essentially a ‘zero discharge’ oilfield in terms of its OVF waste streams from production operations and a large portion of its waste water.

Terralog has injected all of these wastes back into the deep geologic formation sequence, from where the waste originated (i.e. returned the waste streams to place of origin).

Surface pits used for surface disposal sites have either been closed and/or decommissioned.

Terralog and the client are satisfied with the SFI project performance level and environmental achievements of SFI operations at Duri.