Terralog Technologies Inc. – Slow & Easy Stimulation for Enhanced Geothermal Systems (EGS)

Terralog’s clean energy geomechanics services can be applied to geothermal energy applications. Specifically, Terralog’s experience with its Slow & Easy (S&E) stimulation process is readily applicable for deep igneous/stiff low permeability rock for geothermal applications. The extensive stimulation database/know-how Terralog has acquired from its successful S&E service work in unconventional reservoirs (tight and stiff rock) in the upstream petroleum sector, uniquely positions Terralog to provide stimulation services to the developing Enhanced Geothermal Systems (EGS) industry*.

Terralog has expanded its S&E stimulation service to include EGS. The S&E stimulation process is suitable for Stimulated Rock Volume (SRV) development in tight, stiff rock for thermal energy applications:

- S&E stimulation is specifically designed for very stiff and low-permeability rock types – it provides far more effective and controlled conductivity enhancement than conventional massive staged hydraulic fracturing.

- The complex mechanisms of S&E are based on stress and kinematic control factors to develop an in situ Optimized-Stimulated Rock Volume (O-SRV).

- Such an O-SRV is essential to ensure sustained conductivity enhancement of the target formation being stimulated for EGS.

- S&E stimulation is a viable tool for O-SRV development in deep rock EGS and SedHeat applications:

- EGS: use of impermeable rocks for heat energy storage or extraction, but rocks do not have enough porosity and permeability to produce any sustainable fluid flow.

- SedHeat: extraction of energy from hot/warm fluids in sedimentary rock basins.

- S&E stimulation is the convergence of: environmental sustainability – new geo-stimulation technology development – formation injectivity & conductivity enhancement – improved EGS* heat extraction performance.

TTI has proven the success of the Slow & Easy stimulation application for unconventional petroleum resource development. Using this unique experience, TTI is pursuing a global stimulation service for the Enhanced Geothermal Systems industry.

*EGS: An enhanced geothermal system (EGS)

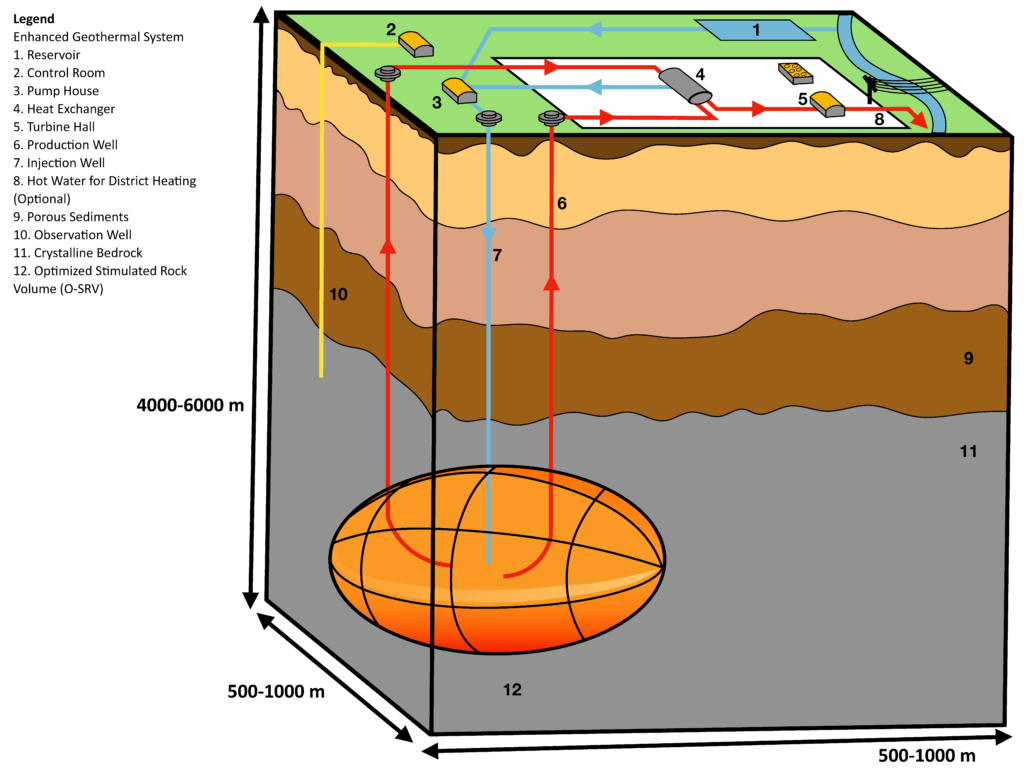

EGS generates geothermal electricity without the need for natural convective hydrothermal resources. Until recently, geothermal power systems have exploited only resources where naturally occurring heat, water, and rock permeability are sufficient to allow energy extraction. However, by far most of geothermal energy within reach of conventional techniques is in dry and impermeable rock. EGS technologies enhance and/or create geothermal resources in this hot dry rock (HDR) through a variety of stimulation methods, including ‘hydraulic stimulation’.**

EGS is the process of injecting water into deep hot rock that has limited fluid content and restricted permeability. If the water is injected at a sufficiently high pressure, this water can ‘stimulate’ the formation by creating a network of complex fractures and ‘enhancing’ the fluid conductivity in situ. Hydraulic fracturing techniques may be used to co-inject proppant to keep the fracture network open. The resultant stimulated rock volume (SRV) can eventually create a geothermal ‘reservoir’ with continued water injection, allowing water to flow through the formation extracting in situ geothermal heat.

A second production well is then drilled into the SRV and the resulting circulation loop brings the hot water to the surface via the production well. At surface the water either flashes to steam or is used to transfer heat to another fluid that produces vapour. This steam or vapour is used to turn a turbine to create electricity. As the final stage in the EGS process, the original produced water is reinjected into the deep hot formation to repeat the geothermal heat extraction cycle. Intermittent stimulation of the rock may be integrated into this cycle to further increase and optimize the SRV development.

**Source: Wikipedia – Enhanced geothermal system – https://en.wikipedia.org/wiki/Enhanced_geothermal_system

View/Download the Fact Sheet ( 中文 | Bahasa Indonesia | عربي )