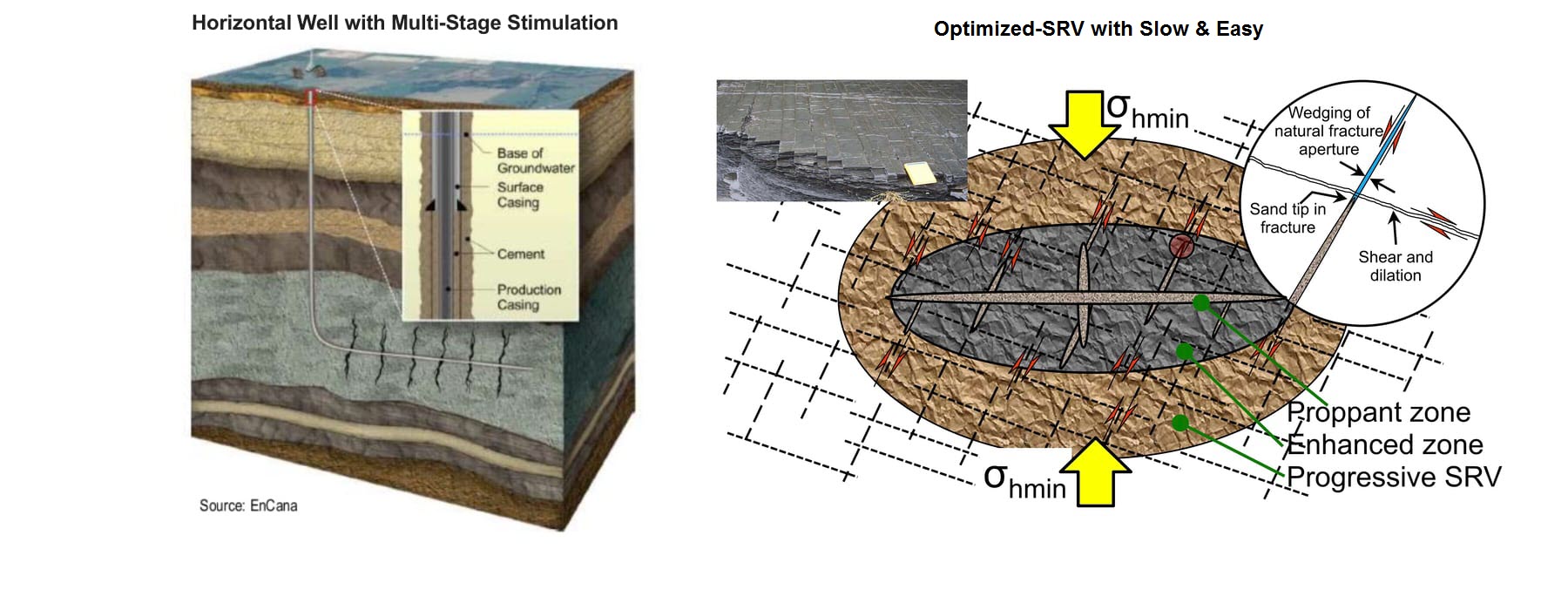

For upstream petroleum industry applications, the ‘Slow & Easy’ Hydraulic Stimulation process is an alternative method developed by TTI for stiff and low-permeability rock types. Slow & Easy stimulation is being used for unconventional hydrocarbon resource development in reservoirs such as shales, tight sands, conglomeratic sands, carbonates, tuff, and CBM. It is an innovative stimulation technique for the development of complex geomechanics resulting in an enhanced fracture network and Optimized-Stimulated Rock Volume (O-SRV) in such formations. The Slow & Easy process is a cyclic injection process with non-damaging, aqueous fluids at lower rates and net pressures to enhance conductivity of the O-SRV. It is designed to improve and stabilize production; and is ideal for re-fracturing applications.

How Is The Terralog ‘Slow & Easy’ Process Different?

The S&E stimulation key differences vs. conventional frac jobs (MSHF):

- Slow & Easy stimulation process utilizes low injection rates, cyclic injection for progressive development of complex fracture networks.

- Lower injection rates (but still maintaining hydraulic fracture conditions).

- Lower injection pressures (but still maintaining hydraulic fracture conditions).

- Cyclic injection approach: cycles related to: treatment, cycles, stages c/w alternating water-proppant pads.

- Lower proppant load (less concentration [less than 3% by volume] and smaller grain size [typically 40/70/100 mesh] ).

- No chemical additives.

- Produced water or brine as frac fluid (fresh water not required).

- S&E stimulation process requires much less horsepower than conventional fracturing methods.

- More cost-effective.

- Reduced equipment & well intervention for stimulation means less cost & reduced risks.

- Improved environmental compliance: improved water management, less noise, no induced seismicity, no frac-hits, mitigates risk of wellbore integrity damage.

Slow & Easy Benefits:

- Reduced environmental impact from stimulation & production operations.

- Improved wellbore integrity, reduced equipment foot print and noise, minimizes usage of chemicals, reduced risk of induced seismicity.

- Improved Water Management: ‘reduce and reuse’ strategies for produced water.

- Optimized Field Development: Reduce number of wells required to develop plays.

- Purpose-built stimulation: customized stimulation method for sustainable recovery.

- Easy to implement:

- Simplified initial well completion or well re-completion.

- Flexible injection strategy to optimize SRV development with petro-physics of reservoir.

- Significantly reduced proppant requirements and no need for chemicals.

- Cost Effective: Significantly more cost-effective than conventional fracturing processes.

- 50%-60% reduction in stimulation cost per well.

- Economic viability for well/field revitalization.

- Sustainable production: mitigate rapid & significant decline rates in unconventional wells.

- Optimized SRV development = improved EUR* over time. (* EUR = Estimated Ultimate Recovery)

- S&E target 70%-200% sustained improvement in oil production (IP~ 10+ months, field cases).

Slow & Easy Objectives:

- Use complex geomechanics for more effective conductivity enhancement and development of the in situ fracture network and O-SRV.

- Achieve more stable & sustainable production rates over the life of the well(s) in tight rock, shales and Naturally Fractured Reservoirs.

- Improved Stimulated Rock Volume characteristics, leading to increased EUR.

- Mitigation of the concerns being raised regarding environmental security of large scale multi-stage hydraulic fracturing (MSHF) for unconventional/shale resource development.

Slow & Easy Value Proposition:

The Slow & Easy process offers significant advantages:

- Significantly reduced stimulation & completion costs

- Less field equipment/personnel mobilization to location

- Reduced usage of proppant and chemicals during stimulation

- Improved water management

- Reduced environmental impact:

- maintain wellbore integrity;

- minimize use of chemicals & fresh water;

- reduced risk of induced seismicity

- Re-fracs: a viable re-frac technique; integrated water management & re-frac operations

- Wellbore asset protection: extends well life; reduced risk of ‘frac-hits’ at offset wells

The S&E stimulation process is the convergence of

environmental sustainability + new geo-stimulation technology + production enhancement + well & field revitalization.

View/Download the Fact Sheet ( 中文 | Bahasa Indonesia | عربي )